Dive watches are some of the most popular watches in the world. They're rugged, reliable, and instantly recognizable. But one question beginners often ask is, "what actually makes a dive watch a dive watch?" It’s not just big lume, a rotating bezel, or a beefy case. There are specific features and standards behind the name. Here’s the beginner-friendly breakdown of to help you navigate the waters.

Water Resistance: The Foundation of Every Dive Watch

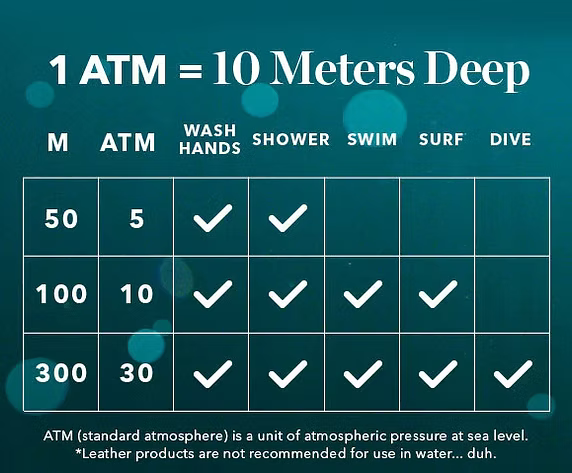

At minimum, a watch needs a water-resistance rating of 100 meters (10ATM) to be considered a dive watch in practice. But if it wants to meet the actual international standard, which you'll hear thrown around as ISO 6425, it must be rated to 200 meters or more and pass a series of pressure, shock, visibility, and corrosion tests. So while many watches look like a diver, an actual dive watch needs at least 100m, and most serious ones are 200m or above.

If you want to understand exactly how water resistance works at a mechanical level, including seals, pressure ratings, what those ATM numbers actually mean in practice, we broke it down here.

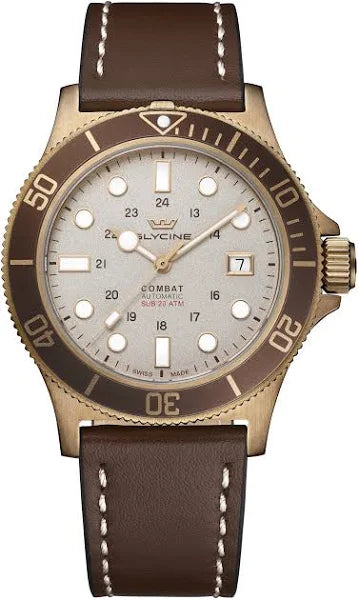

A Unidirectional Rotating Bezel

The bezel tracks elapsed time underwater. When a diver starts their descent, they align the bezel’s zero marker with the minute hand. As the hand moves, they can easily read how long they’ve been underwater. It only turns counterclockwise.

That way, if the bezel is accidentally bumped, it will only shorten the recorded dive time, never lengthen it, keeping the diver safe. This safety-first design is one of the reasons dive watches became so trusted in the first place.

High Visibility: Lume You Can See in the Dark

A proper dive watch must be readable in total darkness, meaning it needs bright, long-lasting lume on hands, markers, and the pip on the bezel's zero marker. High contrast, wide hands, and uncluttered dials are trademark design elements. Underwater, clarity matters more than aesthetics.

A Screw-Down Crown and Caseback

Water is relentless to the point that even microscopic gaps can let moisture in. That’s why dive watches use screw-down crowns and often screw-down casebacks. They do this to create a tight seal which can dramatically improve real-world water resistance and protect the movement from moisture and pressure changes

Durability: Shock, Magnetism, and Corrosion Resistance

ISO 6425 requires dive watches to pass multiple tests. These check that the watch can survive a strong impact (equivalent to 3,000 Gs), can handle exposure to common magnetic fields without losing accuracy, and resist corrosion. Even if a watch doesn’t officially certify to ISO 6425, good dive watches still follow the spirit of these durability standards.

A Legible Minute Hand (Yup, It's Required)

This is one that not a ton of people think about. ISO 6425 explicitly states that a dive watch must have a clearly distinguishable minute hand, since divers use minutes to track oxygen time. Knowing this, it makes sense why many dive watches have oversized minute hands, different shapes for hour and minute hands, and bright contrasting lume on the minute hand. It’s all about safety and quick reading.

The Optional but Common: Helium Escape Valve

This one is frequently misunderstood. You don’t need a helium escape valve unless you’re a saturation diver, which is a tiny group of professional divers working in deep-sea chambers. Most divers and watch enthusiasts will never need this feature, and it’s not required for ISO 6425 certification. It’s just a niche tool for specific environments.

A dive watch is a watch designed to keep you alive underwater.

It must be highly readable, extremely durable, resistant to pressure, and safe even when accidentally bumped or dropped. Even if a watch doesn’t officially carry the ISO 6425 certification, the closer it follows these standards, the more it can legitimately be called a true dive watch.

If you're shopping for a dive watch that checks all these boxes without breaking the bank, take a look at our Islander collection. They're purpose-built divers starting under $300, with 200m water resistance, screw-down crowns, and proper ISO-spec bezels.

Leave a comment